What is the MIL-STD-810 Standard?

MIL-STD-810 is the United States Department of Defense (DoD) standard for environmental testing of equipment to ensure its durability and reliability under various conditions. First introduced in 1967, the standard has undergone multiple revisions, making it a critical benchmark for military and commercial-grade rugged devices. Manufacturers of rugged tablets, including Estone Technology, adopt MIL-STD-810 to demonstrate the robust performance of their products in demanding environments.

MIL-STD-810G and MIL-STD-810H: The Key Differences

The most commonly referenced version is MIL-STD-810G, released in 2008, followed by MIL-STD-810H in 2019. MIL-STD-810H introduced updated testing procedures and stricter criteria for various environmental conditions.

-

A shift in drop test surfaces from plywood-backed concrete to steel-backed concrete.

A shift in drop test surfaces from plywood-backed concrete to steel-backed concrete. -

An increase in the drop height from 4 feet to 5 feet for better real-world impact simulation.

An increase in the drop height from 4 feet to 5 feet for better real-world impact simulation.

-

Method 500 – Low Pressure (Altitude)

Method 500 – Low Pressure (Altitude) -

Method 501 – High Temperature

Method 501 – High Temperature -

Method 502 – Low Temperature

Method 502 – Low Temperature -

Method 503 – Temperature Shock

Method 503 – Temperature Shock -

Method 504 – Contamination by Fluids

Method 504 – Contamination by Fluids -

Method 505 – Solar Radiation (Sunshine)

Method 505 – Solar Radiation (Sunshine) -

Method 506 – Rain

Method 506 – Rain -

Method 507 – Humidity

Method 507 – Humidity -

Method 508 – Fungus

Method 508 – Fungus -

Method 509 – Salt Fog

Method 509 – Salt Fog -

Method 510 – Sand and Dust

Method 510 – Sand and Dust -

Method 511 – Explosive Atmosphere

Method 511 – Explosive Atmosphere -

Method 512 – Immersion

Method 512 – Immersion -

Method 513 – Acceleration

Method 513 – Acceleration -

Method 514 – Vibration

Method 514 – Vibration -

Method 515 – Acoustic Noise

Method 515 – Acoustic Noise -

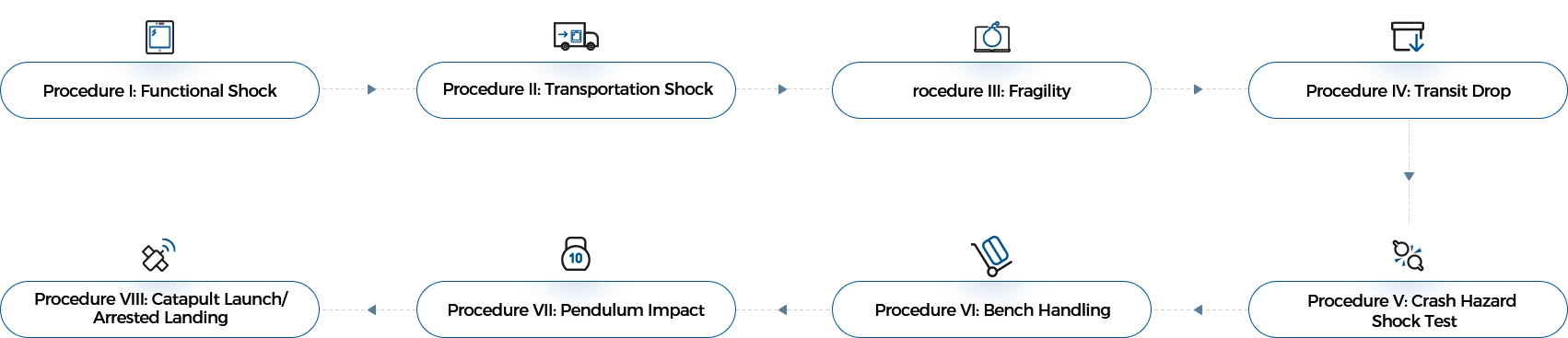

Method 516 – Shock

Method 516 – Shock -

Method 517 – Pyroshock

Method 517 – Pyroshock -

Method 518 – Acidic Atmosphere

Method 518 – Acidic Atmosphere -

Method 519 – Gunfire Shock

Method 519 – Gunfire Shock -

Method 520 – Temperature, Humidity, Vibration, and Altitude

Method 520 – Temperature, Humidity, Vibration, and Altitude -

Method 521 – Icing/Freezing Rain

Method 521 – Icing/Freezing Rain -

Method 522 – Ballistic Shock

Method 522 – Ballistic Shock -

Method 523 – Vibro-Acoustic/Temperature

Method 523 – Vibro-Acoustic/Temperature -

Method 524 – Freeze / Thaw

Method 524 – Freeze / Thaw -

Method 525 – Time Waveform Replication

Method 525 – Time Waveform Replication -

Method 526 – Rail Impact

Method 526 – Rail Impact -

Method 527 – Multi-Exciter

Method 527 – Multi-Exciter -

Method 528 – Mechanical Vibrations of Shipboard Equipment (Type I – Environmental and Type II – Internally Excited)

Method 528 – Mechanical Vibrations of Shipboard Equipment (Type I – Environmental and Type II – Internally Excited)

-

MIL-STD-810G Drop Test (2008-2019)Procedure IV: Devices are dropped from 4 feet onto plywood-backed concrete.

Test Coverage:26 drops covering all faces, edges, and corners. -

MIL-STD-810H Drop Test (2019 and Beyond)Updated to a 5-foot drop onto steel-backed concrete for more rigorous evaluation.

While the drop test is one of the most widely recognized procedures, manufacturers like Estone Technology often conduct additional tests, such as humidity (Method 507) and altitude (Method 500), to meet specific use-case requirements.

-

Drop RatingMIL-STD-810G, 4ft to Plywood

-

Shock RatingMIL-STD-810G, Method 516.6

-

Vibration RatingMIL-STD-810G, Method 514.6